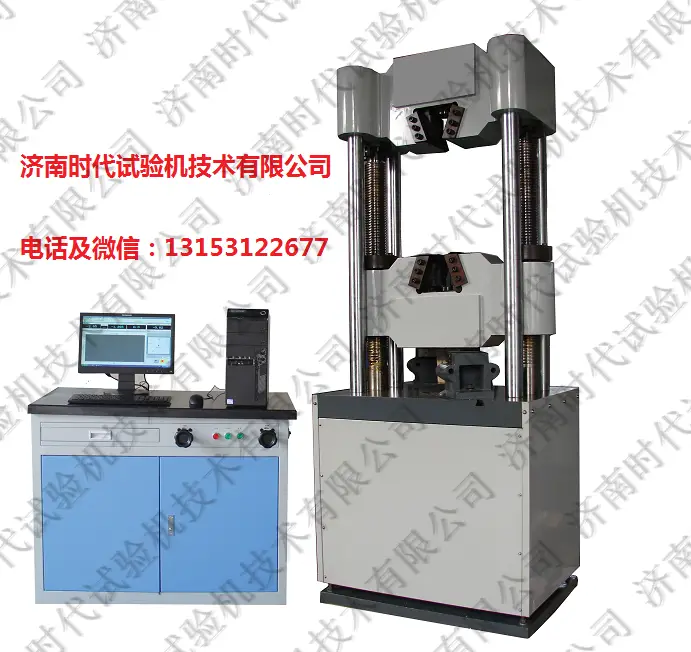

Product Name: WAW-C series microcomputer controlled electro-hydraulic servo universal testing machine

Ji'nan times consulting phone: 131-531-22677

Main uses

WAW-C series microcomputer era Ji'nan testing machine factory production control electro-hydraulic servo universal testing machine is mainly used for metal materials tensile, compression and bending tests of mechanical properties, simple accessories can detect cement, concrete, brick, tile, rubber and rubber products.

The WAW-C series microcomputer controlled electro-hydraulic servo universal testing machine is made up of worm wheel and worm mounted main engine and Qin type oil source control cabinet. The oil pump adopts Italy Mazu Qi import low noise and high performance gear pump. The tensile space is located above the host, and the compression and bending tests are located between the middle beam and the worktable below the host. The adjustment of the test space is realized through the moving beam, and the lifting of the middle beam is driven by the worm and worm. The computer fully automatic closed-loop control high performance electro-hydraulic servo valve to complete the tensile, compression, bending and other tests of various materials. After the test, the experimental results of FM, REH, REL, RPO.2, RP1, RM and elastic modulus E were taken automatically.

Performance characteristics:

1, add a wear-resistant lining between the jaw seat and the jaw plate to prevent the phenomenon of scratching on the inclined surface of the jaw seat during the drawing process, so that the clamping process is more smooth and more reliable.

2, there are various control modes such as isokinetic stress, isokinetic strain, isokinetic displacement, stretching control, program editor and so on. Various control modes can be smoothly switched during the test process.

3, the measurement and control software is based on the Chinese windowsXP operation system platform. It has the characteristics of fast running speed, mild interface, menu hint, mouse operation, multiple sample information input modes, and can meet different material testing. The samples of the samples with the same conditions are automatically generated at one time, and the conditional templates can be made.

4. Automatically store the sample information, test data, test curve and so on after the test is completed automatically.

5, the electro-hydraulic servo universal testing machine can automatically switch to the appropriate range according to the size of test force or the size of material deformation, so as to ensure the accuracy of the test data measurement.

6. The test data (test force, displacement, deformation) loading state and test curve are displayed with the real time screen of the test process.

7. According to the actual needs, stress strain, force displacement, force time, displacement time and other curves can be selected to display, analyze, and print.

8, with automatic and manual two model analysis test results, only using the mouse can find the corresponding corresponding points on the test curve on the test curve.

9, the user can edit standard text report format or EXCEL text report format arbitrarily according to the requirement of the test machine.

10. Automatic overload protection when the load exceeds the full range of 2%-5%

11, all relevant historical records can be automatically inquired according to the sample condition, test date and test data.

8. The database interface is reserved for the software, which is convenient for the local networking in the laboratory and is convenient for the management of the experimental data.

Technical parameters:

Product model WAW-300C WAW-600C WAW-1000C

The structure of the main structure of the worm wheel and worm oil cylinder

Maximum test force 300 kN 600 kN 1000 kN

Test machine level 1 level /0.5 level

Range of test force measurement 1%-100%FS

The value of the relative error is less than or equal to the 1% value of test force

Force resolution 1/300000

Deformable measuring device electronic extensometer

Relative indication error is less than or equal to + 0.5% deformation

Photoelectric encoder of displacement measuring device

The value of the relative error is less than or equal to the value + 1%/0.5% displacement

Displacement resolution 0.01mm

The maximum moving speed of the piston 0.05-100 (mm/min) without pole speed regulation

Beam adjustment speed 150 (mm/min)

Control mode three closed loop control and programming control

Mechanical limit protection and software overload protection for safety protection device

Effective stretching space 650mm

Effective compression of space 550mm

Column spacing 530mm 650mm 760mm

Hydraulic automatic clamping by means of clamping

The diameter of a circular specimen with a diameter of 6- [Phi] 20mm, 10-, 30mm, 13- and 40mm

0-10mm 0-15mm 0-30mm of flat specimen holding thickness

Flat specimen holding width 76mm 80mm 70mm

Up and down pressure plate size 204*204mm

Bending distance of 600 mm

Width of bending roller 140mm

Maximum piston stroke 250mm

The mainframe size (mm) 1000 * 600 x 23651180 * 750 x 750 x 800 x 2965

Host power 1.1KW 1.1KW 3KW

Shape size of oil source control cabinet (mm) 960 * 630 x 900960 * 630 x 900960 x 630 x 900

Control cabinet power 1.5 KW 1.5 KW 2.2 KW

Host machine weight 3000kg 3500kg 5600kg